CASING ACCESSORIES

Providing under-reamed centralizers specifically to compress and glide, the stand-off in the Open Hole Section.

The Next Generation in Centralization

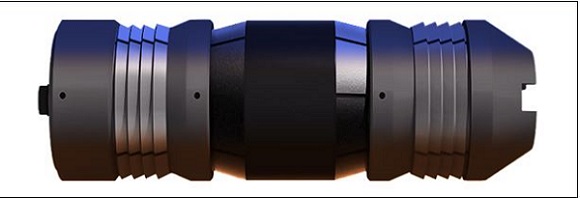

PHAZER

Under-reamed centralizer designed to compress & glide through the previous cased hole restrictions, espanding & recovering to provide a high level of Stand-off in the open.

- Engineered for under/reamed application

- Innovative variable blade design. Each blade working independently during insertion and RIH.

- Superior Stand/off guarantees improved zonal isolation.

- Significantly reduced running forces reduces accumulative drag forces during RIH

- API testing and beyond, operators testinOpenhg requirements will be met

- One piece robust construction, suitable for rotation, withstanding high radial 1 axial loads

- Flexibility - proprietary manufacturing process, and high strength spring steel material offers a centralizer that performs equally in close tolerance cased hole and open hole applications

- Sizes tested and available -5-1/2" -24"

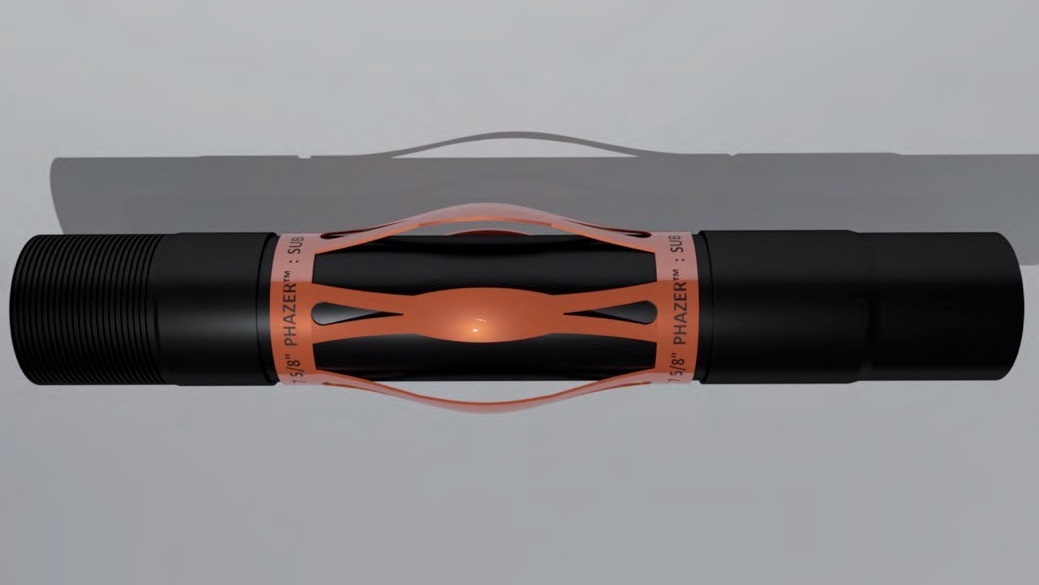

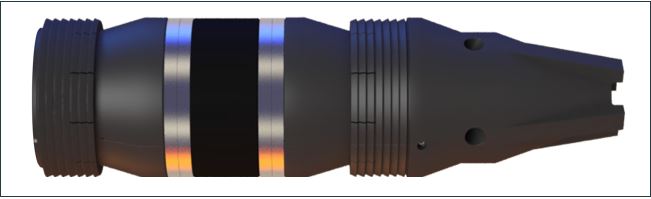

PHAZER: SUB

The PHAZER: SUB In-line centralizer sub is specifically designed for passing through long sections of previous casing with annular clearances < 0.75" & recovering to provide the best conditions for good zonal isolation in under-reamed open hole sections

- Engineered for under/reamed application

- Innovative variable blade design. Each blade working independently during insertion and RIH.

- Superior Stand/off guarantees improved zonal isolation.

- Significantly reduced running forces reduces accumulative drag forces during RIH

- API testing and beyond, operators testing requirements will be met

- Robust construction, suitable for rotation, withstanding high radial / axial loads

- One piece robust construction, suitable for rotation, withstanding high radial & axial loads

- Flexibility - proprietary manufacturing process, and high strength spring steel material offers a centralizer that performs equally in close tolerance cased hole and open hole applications

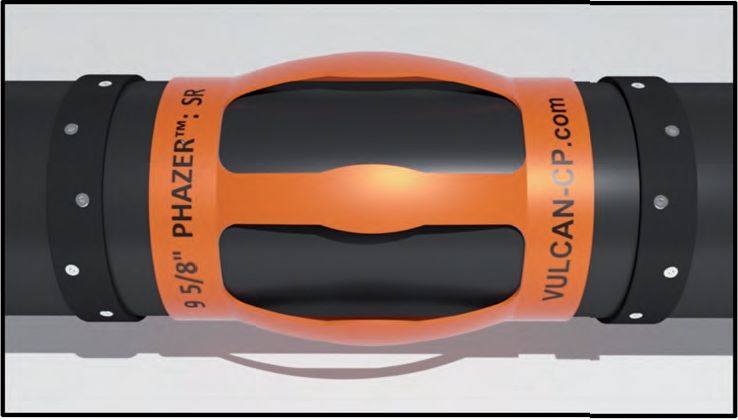

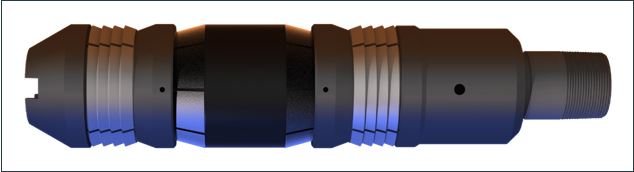

PHAZER: SR

The PHAZER: SR is a one piece heavy duty centralizer that has been specifically designed for gauge hole centralization, offering 100% stand-off

- Heavy Duty One Piece Construction providing flexibility and strength

- Suitable for rotation, withstanding high radial & axial loads.

- Zero Starting & Running forces.

- Maximised Stand-off & Flow-by

- High Restoring force exceeding API requirements. Superior Stand-off guarantees improved zonal isolation

- Suitable for onshore installation reducing health and safety risk and reducing rig time

- One piece robust construction, suitable for rotation, withstanding high radial & axial loads

- Split & hinged option available upon request

- Sizes tested and available -4½" -30"

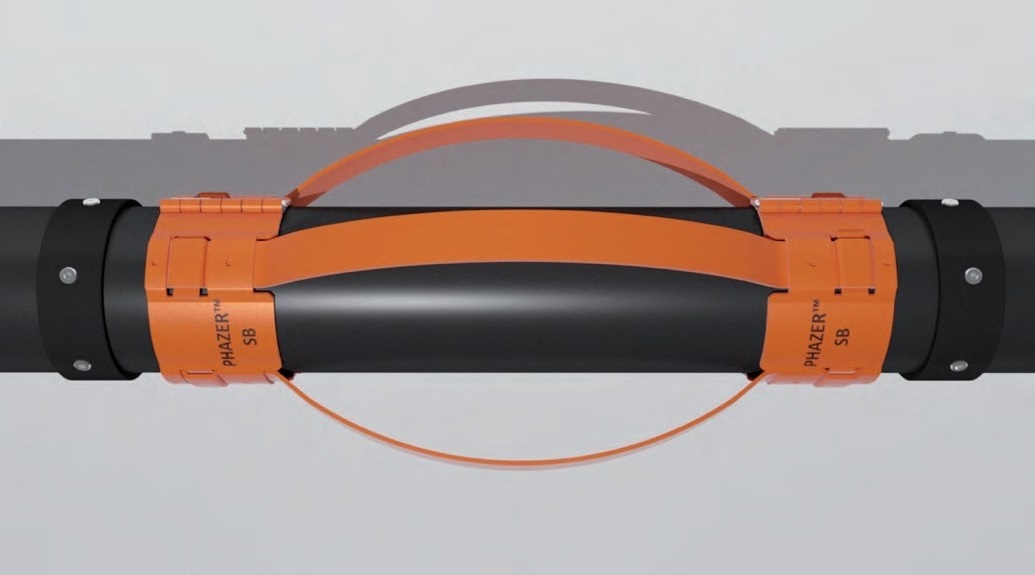

PHAZER: SB

The PHAZER: SB - API qualified range of welded & non-welded bow spring centralizers.

- Engineered hinged welded & non-welded spring-bow centralizers

- SB Range

- Positive Blade

- Tandem Rise Blade

- Conventional Blade

- API 10 D Certified

- High restoring force

- Low starting & running forces

- API - ISO 9001:2015 rated manufacturing and quality control

- Size Range 2-7/8" -30".

PHAZER: FUSION

The PHAZER: FUSION is an ultralow friction Kevlar composite solid body centeralizer designed specifically to reduce torque and drag in challenging ERD wellbores.

- The Bulletproof Kevlar composite - high strength, high impact resistant centralizer.

- Diamond ceramic construction provides extreme wear resistance for axial and radial loading.

- Suitable for HPHT wellbores, the Phazer: Fusion does not degrade overtime as per certain synthetic centralizer materials.

- PTFE honeycomb structure provides exceptional coefficient of friction, affording low torque and drag during RIH.

- Suitable for long horizontal and extreme ERD wellbores

- Free flow 360° solid blade design provides excellent cement placement and guaranteed stand-off.

- Centralizer placement / T&D analysis available.

- Size available 2-7/8" -9 5/8".

PHAZER: ZR

The PHAZER: ZR is a low friction zinc alloy & Carbon Kevlar Composite solid body centralizer designed specifically to reduce torque and drag in Extreme ERD applications.

- Combination of Zinc Alloy & Bulletproof Carbon Kevlar ultra-low friction durable materials.

- Exceptionally low coefficient of friction providing low torque and drag during RIH.

- Suitable for highly deviated and ERD applications.

- High strength for axial and radial loading.

- Exceptionally durable materials suitable for high temperature wellbores and long-life cycles

- Full 360° passive spiral blade, maintaining maximum flow-by area.

- Free flow solid blade design provides excellent cement placement and guaranteed stand-off.

- Centralizer placement/T&D analysis available

- Machinable for bespoke design and reduced OD sizes

- Split option available.

- Sizes available 4 1/2” – 13 3/8”.

PHAZER: Z

The PHAZER: Z is a low friction zinc alloy solid body centralizer designed specifically to reduce torque and drag in Extreme ERD applications.

- Low coefficient of friction providing low torque and drag during RIH.

- Suitable for long horizontal and ERD wellbores.

- High strength for axial and radial loading.

- Exceptionally durable materials suitable for high temperature wellbores and long-life cycles

- Full 360° spiral blade.

- Free flow solid blade design provides excellent cement placement and guaranteed stand-off.

- Centralizer placement/T&D analysis available

- Machinable for bespoke design and reduced OD sizes

- Split option available.

- Sizes available 2 7/8” – 13 5/8”.

PHAZER: ECO

The PHAZER: ECO is a fabricated steel solid body gauge hole centralizer suitable for intermediate well bores.

- One piece steel, heavy duty centralizer.

- Suitable for intermediate well bores.

- Positive stand-off & Maximised flow-by.

- Free flow solid blade design improves cement placement.

- Bi-directional fitment

- Excellent side loading > 20 tonnes.

- Spiral bladed or Straight Blade options available

- Integral stop collar option available

- Sizes available 2 7/8” – 30”.

COMPLETION ACCESSORIES

PHAZE-LOK: KEVLAR

The PHAZE"LoK Kevlar Composite bonded on stop collar that accompanies the Vulcan Phazer Under-Reamed centralizers. This virtually indestructible and bulletproof stop collar provides exceptionally high holding forces, Ideal for tight/close tolerances application.

- A moulded and bonded stop collar.

- Moulded directly onto casing/liner and sand screen joints.

- Maximised flow by area and reduced ECD's.

- Extremely high holding force in excess of 50 tonnes.

- Non-metallic, fully millable and drillable material

- Fully compatible with Chrome Tubulars.

- No set screws or the potential for carbon impregnation.

PHAZE-LOK

A full range of high holding force stop collars to accompany the Vulcan centralizer product lines.

- PHAZE-LOK HD.

- Heavy Duty

- Tapered leading edge

- High Holding force >20 tonnes

- Offset Knurled Set Screws

- Stainless Steel Suitable for Chrome Tubulars

- Run in conjunction with Phazer under-reamed and SR centralizers

- PHAZE!LOK DI.

- High Holding Force >15 tonnes

- Heavy Duty casting suitable for Chrome tubulars

- Knurled stainless steel set screws

- Run in conjunction with Phazer Fusion and ZA centralizers

- PHAZE!LOK ECO.

- Standard Stop Collar

- Good holding force >10 tonnes

- Stainless Steel Knurled Set Screws

- PHAZE!LOK HINGED.

- Hinged with set screws

- Hinged with spiral nail

- Hinged with bolt

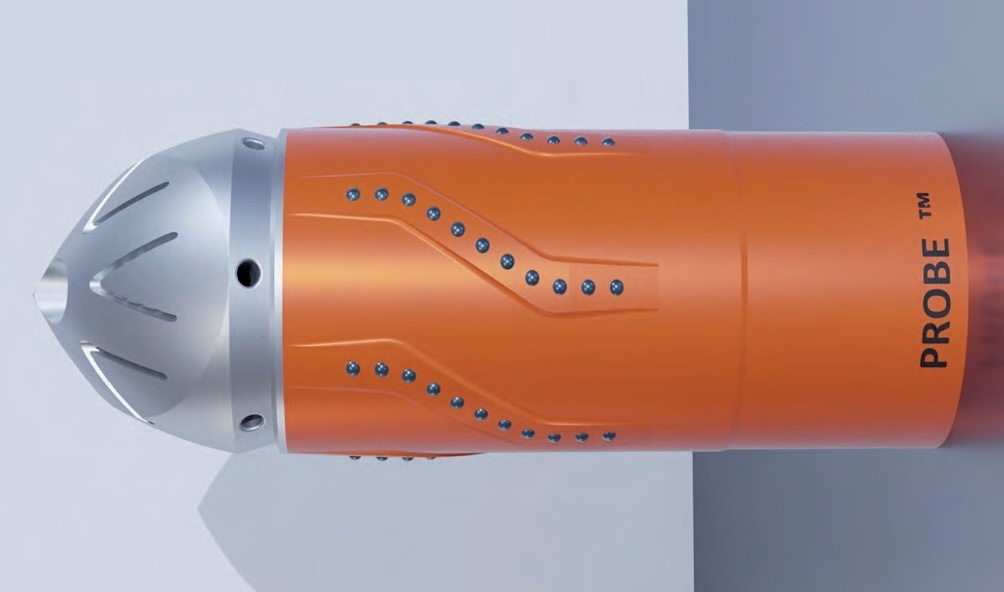

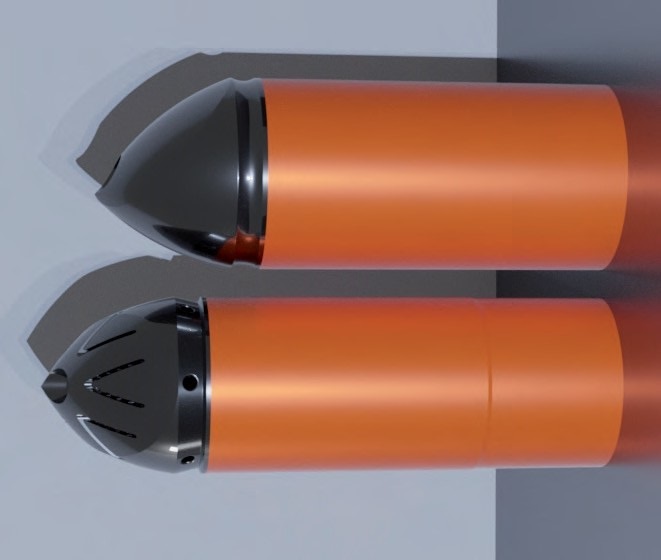

PROBE: RS

A sophisticated range of Reamer & Guide Shoes designed to assist casing/liner/screen running when difficult hole conditions are anticipated.

- High strength Eccentric Well bore seeking nose.

- Profiled nose design reduces drill-out times whilst maintaining unit strength and integrity.

- Flow Ports offer 351° flow area coverage aiding hole cleaning and cement placement,.

- Right hand blade design offers a more aggressive reaming action.

- Optimized cutting structure offers the capability to ream past obstructions with rotation or by reciprocation

- Tungsten Carbide cutting structure

- High Flow 5Kpsi & 10Kpsi Valve exceeding API 10F IIIC certification.

- Single, Double & Au$o-Fill Valve options available

- Various cutting structure options available

- Nose available in Aluminium or Phenolic, Concentric or Spade

- Fully drillable with PDC & Rollercone bits

PROBE: GS

A sophisticated range of Reamer & Guide Shoes designed to assist casing/liner/screen running when difficult hole conditions are anticipated.

- High strength Eccentric Well bore seeking nose.

- Profiled nose design reduces drill-out times whilst maintaining unit strength and integrity.

- Flow Ports offer 351° flow area coverage aiding hole cleaning and cement placement,.

- Slick Body allow for easy passage through swelling , collapsed wellbores.

- Slick Body eliminates pack off potential

- High Flow 5Kpsi & 10Kpsi Valve exceeding API 10F IIIC certification.

- Single, Double & Auto-Fill Valve options available

- Various cutting structure options available

- Nose available in Aluminium or Phenolic, Concentric or Spade

- Fully drillable with PDC & Rollercone bits

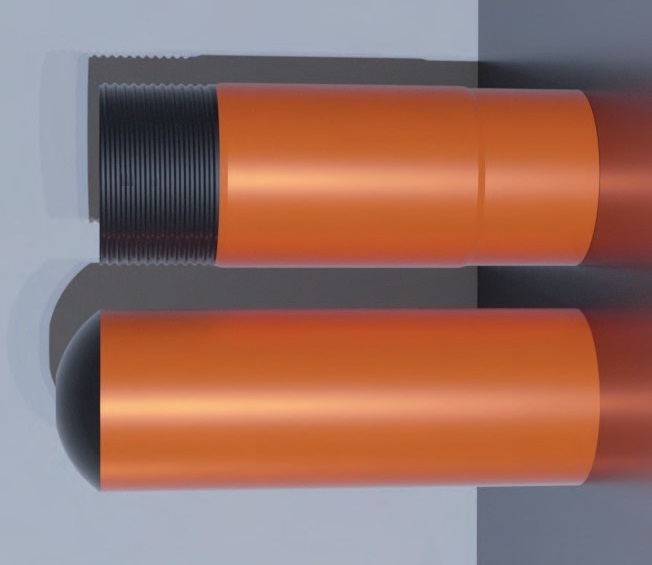

FLOAT EQUIPMENT

A full range of guide shoes and premium float equipment, that surpasses API 10F IIIC and manufactured in accordance to API 5CT. Suitable for applications such as full casing strings and close tolerance liners

- Durable Eccentric & Concentric Profiled Nose available in standard Aluminium. Cement or Phenolic.

- Up Jet / Down Jet side ports available.

- Back Pressure 5,000psi * 10,000psi'.

- Temperature Rating up to 400° F

- Single, Double & Auto-Fill Valve options available.

- Ball Catcher/Deflector options available.

- Fully drillable by PDC & Roller Cone drill bits

- Conventional and Non-Rotating Cement Plugs available.

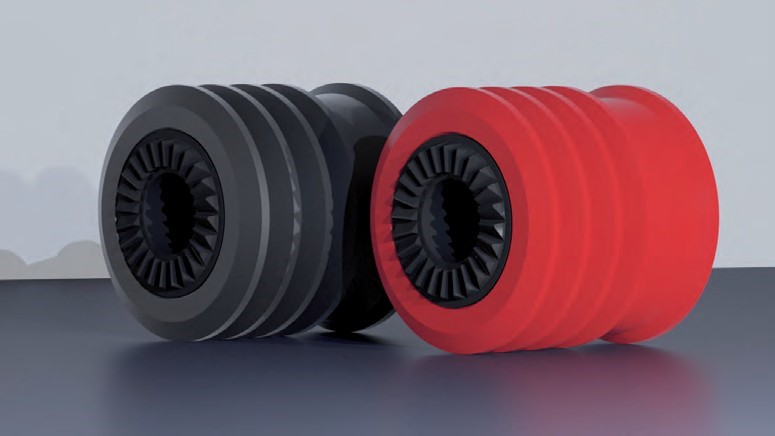

CEMENT PLUGS

A full range of premium cementing plugs that surpasses API 10 TR6.

- Conventional and Non-Rotating Cement Plugs.

- Five fin for superior clean casing wipe.

- Sure-Lok anti-rotational design eliminates potential for drill out issues.

- Tapered insert and receptacle for secure plug landing.

- High Bump Pressure options available up to 10ks.'

- Operating range up to 400°F.

- Rupture Disk rating as per Operators requirements. 300psi - 800psi.

- Full& drillable by PDC & Roller Cone drill bits.

- Compatible with all common downhole WB and OB fluid types.

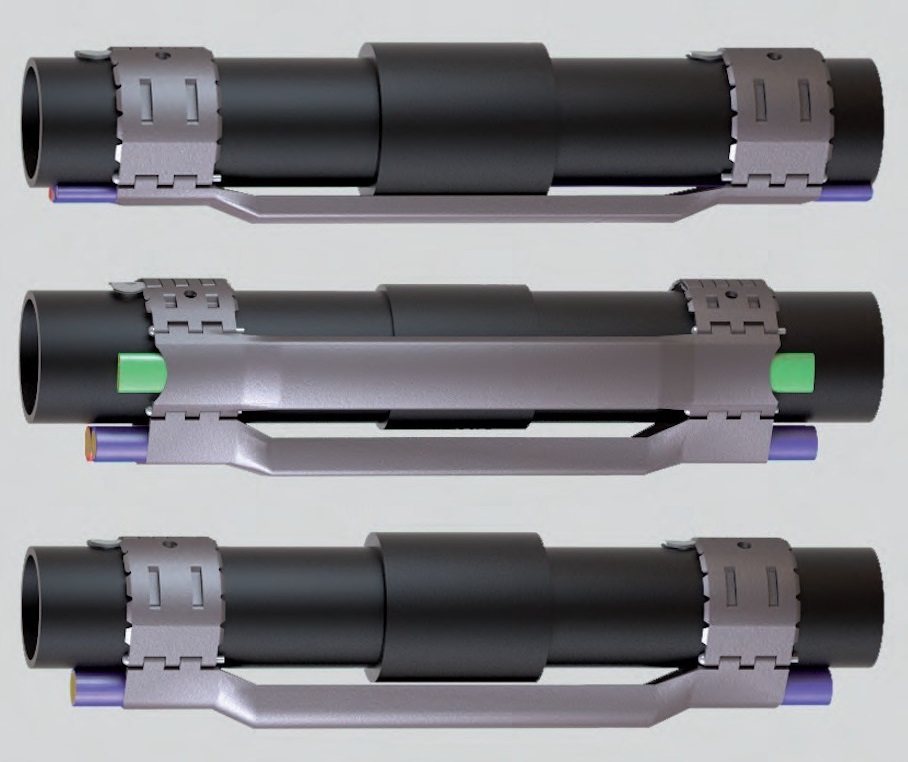

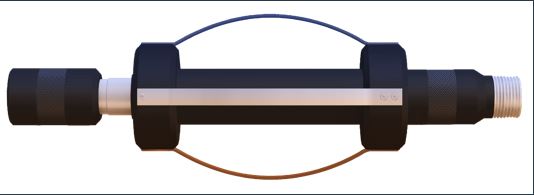

KLING-ON

The KLING-ON range provides downhole cables and control lines with protection during RIH" both across the coupling and at mid joint on the pipe.

- Engineered cross coupling control line protector.

- Supports and protects cables & control during trips in and out of wellbore.

- Long channel design eliminates crimping /damage to the control lines/cable. This effectively increases the life cycle of the downhole equipment.

- Eight point holding force system - allowing for Max - Min API pipe tolerances.

- Tapered holding points offer greater holding force without damaging the control line/cables

- Carbon or Stainless Steel construction with galvanized coating.

- Single/Dual/Mid joint options available

- Custom designs available for all configurations.

BRIDGE PLUG

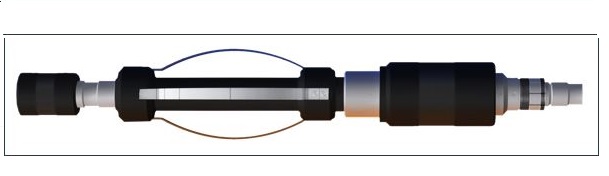

MWB WIRELINE SET BRIDGE PLUG - MWB TOP SET

Model MWB is compact, small OD and designed as a high performance drillable bridge plug suitable for almost any temporary or permanent plugging operation. The plug is constructed from select materials which provide a combination of strength and drillability.

Special Features

- Sets securely in all standard hardness casing.

- Ratchet lock rings secure dynamic setting force. Faster and safer run.

- One piece packing element and metal back up rings combine for a superior seal.

- Can be set directly with Baker wireline setting tools.

- Shear studs are Baker style and connect directly to the Adjuster Sub.

MWB-1/MMB

Model MWB-1 Wireline Set and MMB Mechanical Set Bridge Plugs are used to isolate zones for temporary or permanent abandonment. These drillable Bridge Plugs set securely in all standard hardness casing. A ratchet lock ring stores the setting force in the Bridge Plug. The one piece packing element and metal back up rings combine for a superior seal. The case hardened, one piece slips virtually eliminate premature setting, yet can be easily drilled out. Set with Model MSB Mechanical Setting Tool. They are available for 4-1/2” through 20” casing.

It can be converted to Cement Retainer by changing out the guide and replacing the bridging plug with the correct valve assembly.

Special Features

- Sets securely in all standard hardness casing.

- Ratchet lock rings secure dynamic setting force. Faster and safer run.

- One piece packing element and metal back up rings combine for a superior seal.

- Pressure balanced sleeve valve is opened and closed by tubing manipulation from surface for better control.

- Easily convertible from wireline set to mechanical set by adding a shear screw and changing the upper slip.

WRBP WIDE RANGE BRIDGE PLUG

Wide Range Wireline Set Bridge Plugs are specially designed to run through tubing or restricted pipe and set

securely in larger tubing or casing below. These Bridge Plugs will set securely in any hardness casing. A ratchet lock ring stores the setting force in the Plug. The three piece packing element and metal back up rings combine for a superior seal. The case hardened, one piece slips virtually eliminate premature setting, yet can be easily drilled out. They are available for 1.610” through 4.276” setting range.

Special Features

- Sets securely in all standard hardness casing.

- Ratchet lock rings secure dynamic setting force. Faster and safer run.

- One piece packing element and metal back up rings combine for a superior seal.

- Compact, easy running.

- Can be set either with GO, Baker or Gearhart wireline setting tools.

- 5.8” sucker rod thread on the bottom shoes to accomodate a centralizer and other tools

HYDRO-MECHANICAL BRIDGE PLUGS -HYDRO-MECH

Hydro-Mech Bridge Plug is a hydraulically actuated, mechanically set bridge plug that is designed for easy drillout. It can be used in zonal isolation for squeeze cementing, fracturing, and plug and abandonment applications. The setting mechanism is built-in. A ball is placed in the tubing string plugging off the built-in equalizing ports. Pressure is then applied to set the top slip and then mechanical pull is applied to finish the set. Releasing the tubing string from the plug is done by simply turning to the right

Special Features

- Sets securely in all standard hardness casing.

- Ratchet lock rings secure dynamic setting force. Faster and safer run.

- One piece packing element and metal back up rings combine for a superior seal.

- Pressure balanced sleeve valve is opened and closed by tubing manipulation from surface for better control.

- Easily convertible from wireline set to mechanical set by adding a shear screw and changing the upper slip.

STINGER SEAL ASSEMBLY

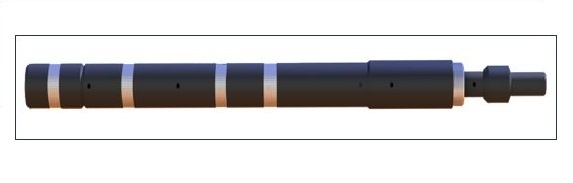

MSS STINGER SEAL ASSEMBLY

The MSS Stinger Seal Assembly is a tubing conveyed latching seal assembly that is used to operate the sleeve valve

in an MWR Cement Retainer previously set on wireline. The MSS should always be run in conjunction with a MTC Tubing

Centralizer to provide easier entry into the Cement retainer. It features a snap-in, snap-out type latch that

provides a surface indication of the stinger being landed into or removed from a retainer. The latch system

allows the cement retainer valve to be opened and closed while the stinger

remains latched and sealed in the bore of the retainer. This allows easy testing of the tubing before pumping cement.

Special Features

- Provide positive control when the work string is picked up to close the sleeve valve.

- Re-engages each time the work string is lowered to open sleeve valve.

- Helps prevent seal from pumping out during pumping operations or tubing testing.

- One size operates several sizes of retainers.

- Rotate or Snap-out release.

- Can Run with Cement Retainers.

TUBING CENTRALIZER

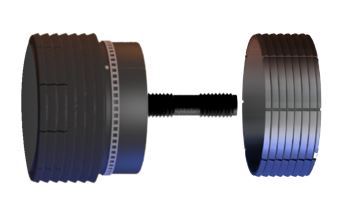

MTC TUBING CENTRALIZER

MTC Tubing Centralizer is used to center the tubing and

provide easier entry into an MWR Cement Retainer previously set by wireline.

It is made up above the stinger seal assembly and provides a centering device

for entering the retainer bore.

Special Features

- Provides positive control and allows one size.

- Tubing centralizer covers a large range of casing weights.

- Most parts are interchangeable with the MSR Mechanical Setting Tool.

- Allows tubing torque to be transmitted to tools below.

- Can Run with Cement Retainers.

CEMENT RETAINER ACCESSORIES

M CONVERSION KITS

M series CR products can be easily converted

to perform as a Slide Valve Cement Retainer, or a Bridge Plug. In addition, all sizes may be converted for electric line

setting or mechanical setting by selection of proper upper slip and the appropriate running tools.

SLIDE VALVE CEMENT RETAINER

The Slide Valve Cement Retainer utilizes a slide valve which is pressure balanced in the closed position to

reliably contain high fluid pressures, and opens at high pressure differential.

Please refer to MWR and MMR for detailed information about Slide Valve Cement Retainers

BRIDGE PLUGS

Simple inexpensive “bridging plug” is now

available in three sizes to convert Slide Valve Cement Retainers (both wireline set and tubing set)

to Bridge Plugs. The Bridge Plug is held trapped between shoulders in the retainer body and valve shoe

HYDRAULIC SETTING TOOL

MHSB

Model MHSB Hydraulic Setting Tools are used to run and set

packers, bridge plugs and cement retainers on a work string, production tubing or coil tubing. After dropping a ball, the setting tool translates hydraulic pressure applied to the tubing to a force transmitted throughout the adapter kit to the slips and pack off the sealing element of these tools. It allows setting in deviated wells where it is often difficult to use electric wireline equipment. While running in the hole, the setting tool automatically fills with well bore fluid and remains balanced to prevent premature setting. After setting the packer, bridge plug or cement retainer, the coil tubing or tubing string and the setting tool can then be retrieved, while allowing the well bore fluids in the tubing to discharge through bypass ports in the tool.

Special Features

- Simple proven operation.

- Uses the same adapters for running as are used with a Baker 10#.

- or 20# setting tool.

- Automatically fills and drains.

- Hydraulically balanced while running in the hole to prevet premature setting.

- Can withstand high tensile loads

- Two-stage cylinders are standard

- No rotation required

- Can be provided with IF connections

MECHANICAL SETTING TOOL

MSB MECHANICAL SETTING TOOL

Model MSB Mechanical Setting Tools are used to mechanically

set MMB Bridge Plugs. It is designed to contain the upper slips of Bridge Plug in

a safe retracted position while running to setting depth. The upper slips are released by

right hand rotation and slacking off on the work string.

Special Features

- Special designed Bow Spring provide positive control and

allows one size Mechanical Setting Tools to cover a large range of casing weight.

- Locked with Bridge Plug.

- The Upper slips are held in a safe retracted position while running Can quickly be configured to set MMR Cement Retainers.

- These tools can be used to run a number of Competitive brand Baker style bridge plugs.

MSR MECHANICAL SETTING TOOL

Model MSR Mechanical Setting Tools are used to mechanically set MMR

Sleeve Valve Cement Retainers. This tool incorporates both a stinger seal assembly and mechanical

setting function. In addition, it has a built in snap latch, allowing the tool to be latched into

the cement retainer with set down weight and released with either up strain or right-hand rotation.

The sleeve valve on the cement retainer is in the open position while being run in the well.

When the setting procedure is completed, the sleeve valve may be closed by picking up two inches

at the tools or opened by slacking off two inches. The snap latch feature allows the sleeve valve

to be shifted open or closed while the tubing is still anchored to the retainer.

Another feature of the tool provides for running the sleeve valve either open or closed.

Normally the valve is run open so the tubing may fill. However, for pressure testing the tubing,

while running, the valve can be run closed. Cement Retainers can be set and pressure tested in a

single trip.

Special Features

- Special designed Bow Spring provide positive control and

allows one size Mechanical Setting Tools to cover a large range of casing weight.

- The upper slips are held in a safe retracted position while running.

- Allows users to set, pressure test tubing, and squeeze in a single trip.

- Can quickly be configured to set MMR Cement Retainers or MMB Bridge Plugs.

- These tools can run standard Baker style plugs or retainer

RETRIEVABLE PACKER

PC-1 RETRIEVABLE PACKER

Model PC-1 Retrievable Packers are used for a variety of well treating and producing operations

including squeeze cementing, formation fracturing, acidizing and testing. The PC-1 is a versatile

tension set tool that holds differential pressure from above and below. It has a full opening

bore that allows unrestricted fluid flow and easy passage of wireline tools. It is ideal for

straddle operations using the Retrievable Bridge Plug. They are available for 3-1/2” through 9-5/8”

casing.

Special Features

- Sets securely in all standard hardness casing Full opening bore, thick

wall, one piece body Three piece packing element system.

- Holds differential pressure from above and below.

- Used where shallow setting depth prevents use of compression set packers.

- Can be used with PCU-1 Unloader.

- Field-proven design, recommended to 275 degrees F applications

- if application need high temp, please contact MAP

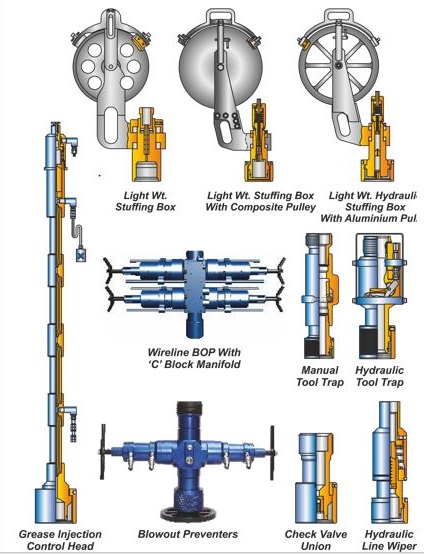

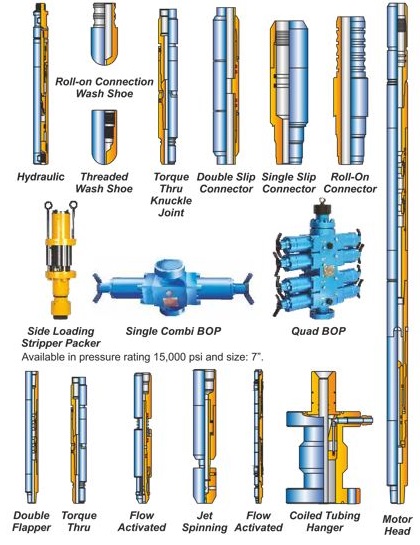

WELL SERVICES

Hot Oil Pumping Unit

Cementing Unit

Blender

Data Acquisition Unit

Frac Pumping Unit

All items available in pressure rating 15,000 psi and size: 7”.

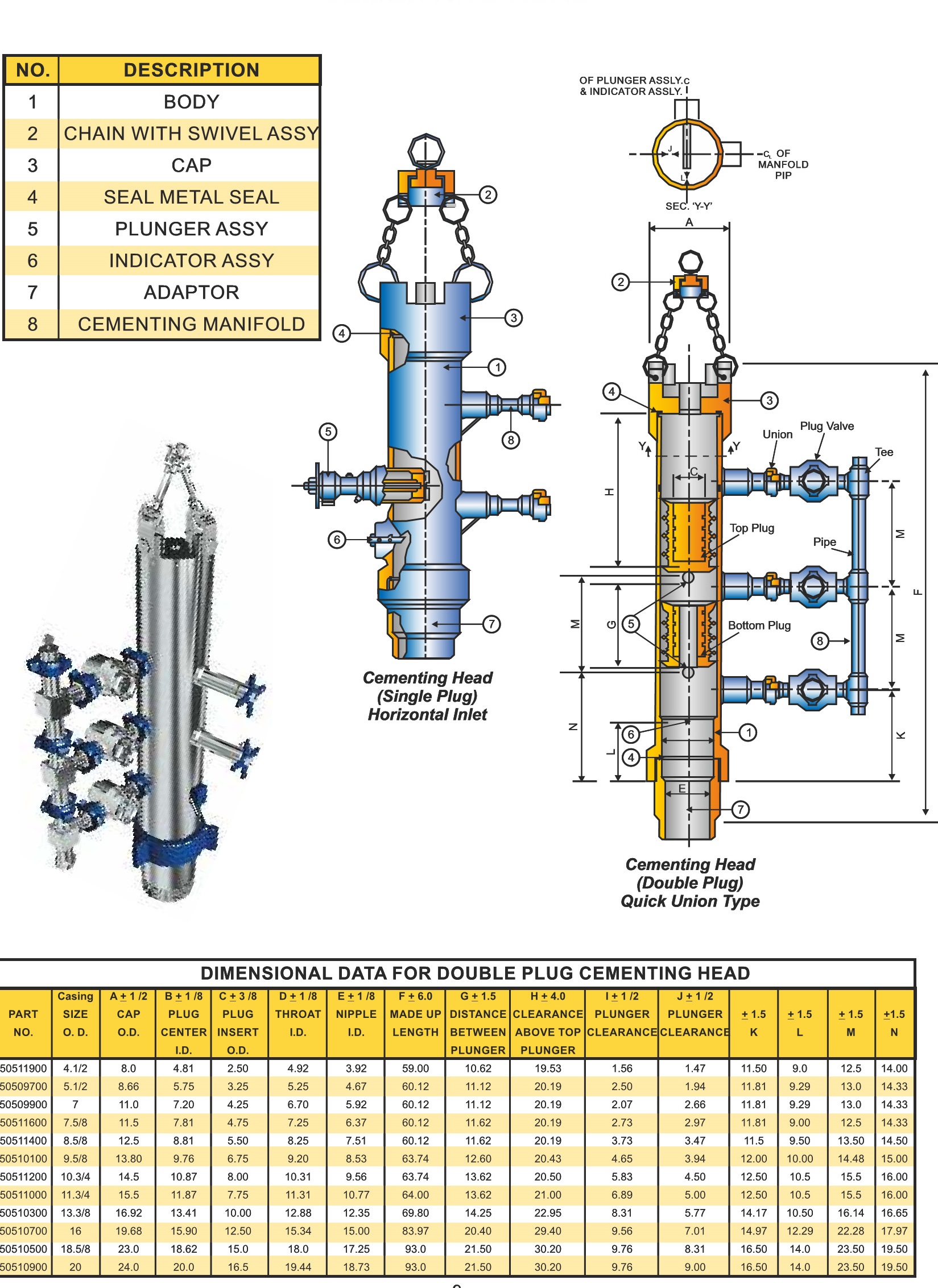

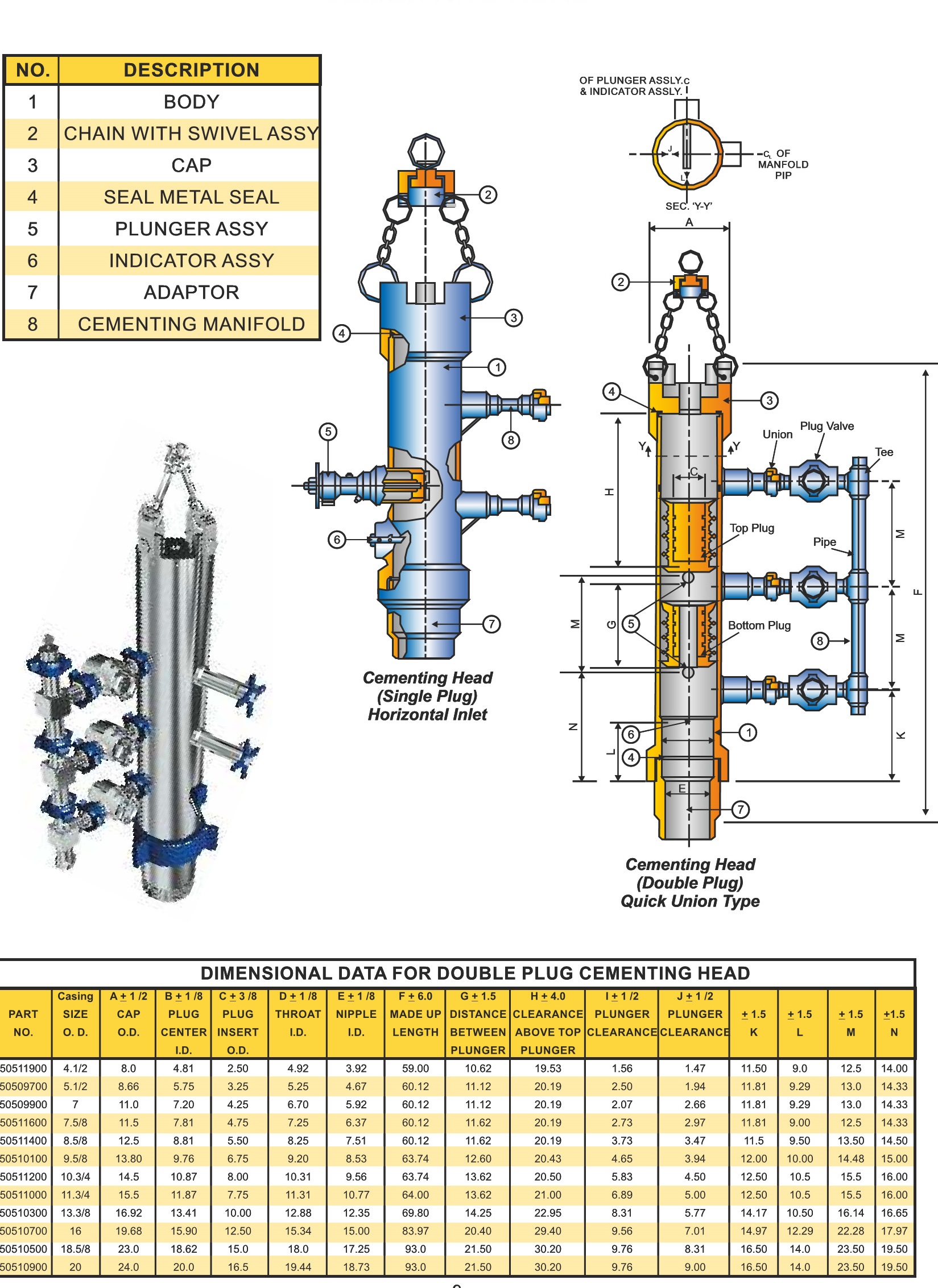

Cementing Head

Flanges & Fitting