Chisida is the official representative of Volant in Nigeria. We are here to facilitate your ownership of all Volant Products, accessories as well as provide you with needed training and support. We are in this industry to serve you.

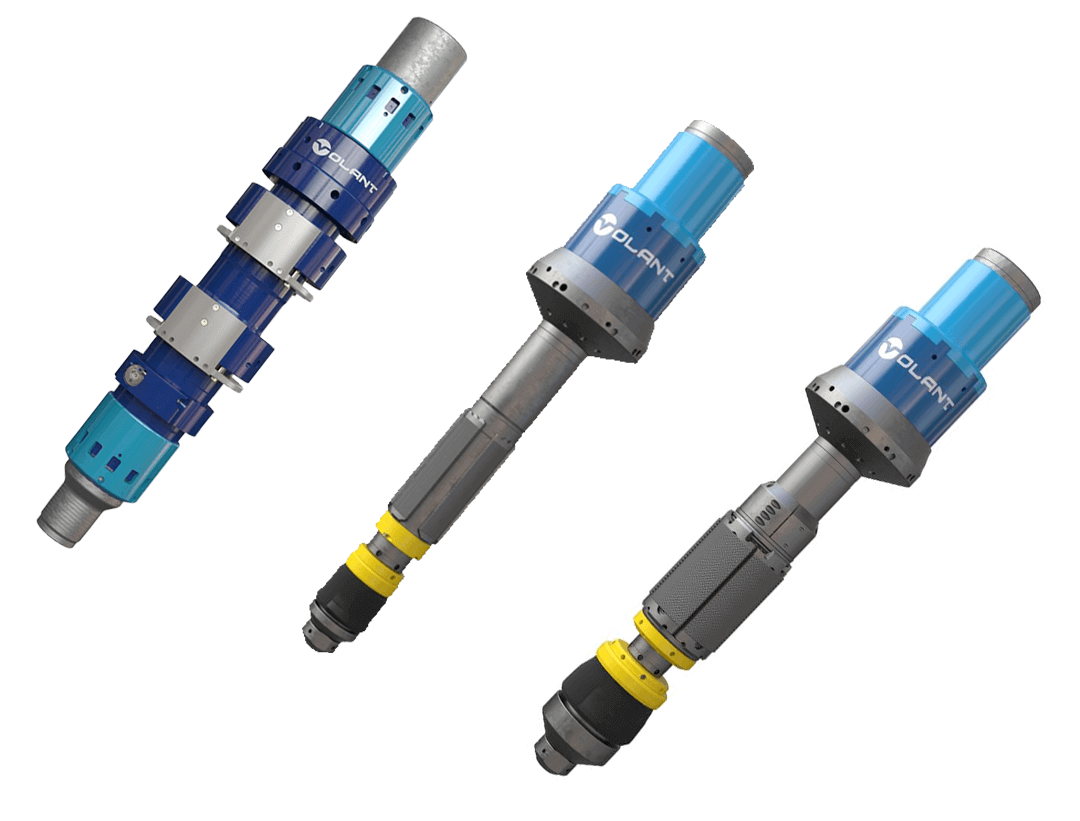

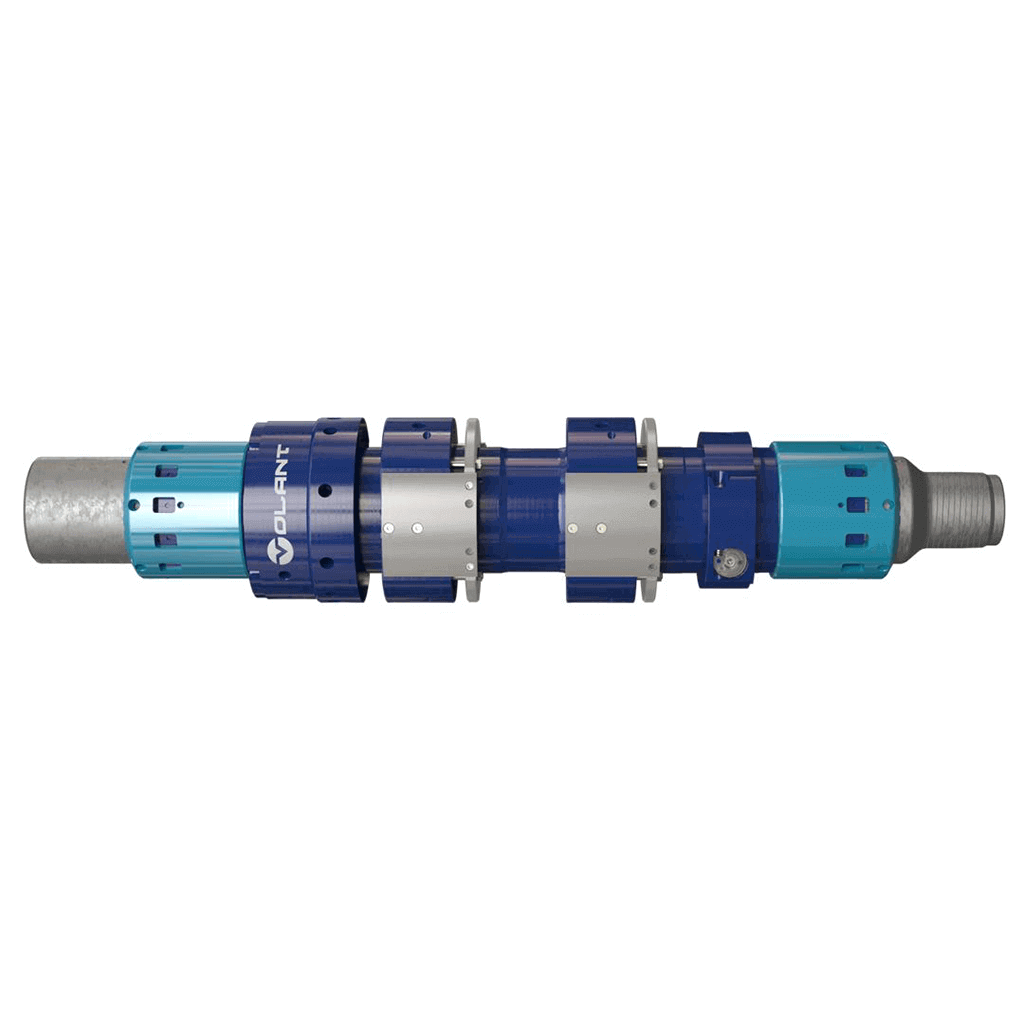

Volant’s CRTi®️ casing running tools are fully mechanical and designed for casing running or drilling with top drive equipped rigs to make-up, breakout, reciprocate, rotate, fill, circulate and cement casing and liner strings, reducing non-productive time and associated costs. Starting from the insertion diameter of the base tool (cage OD), selectable sizes of integral jaws/ dies are used to configure the CRTi to support gripping casing of increasing internal diameter. Through the use of a patented extended reach die structure, the gripping diameter can be further increased to include casing sizes much greater than the base tool. The standard CRTi tool uses intuitive operations for pipe engagement and release – stab, rotate to the right to engage and reverse to disengage. A simple rig-up and rig-down further increases operational efficiency.

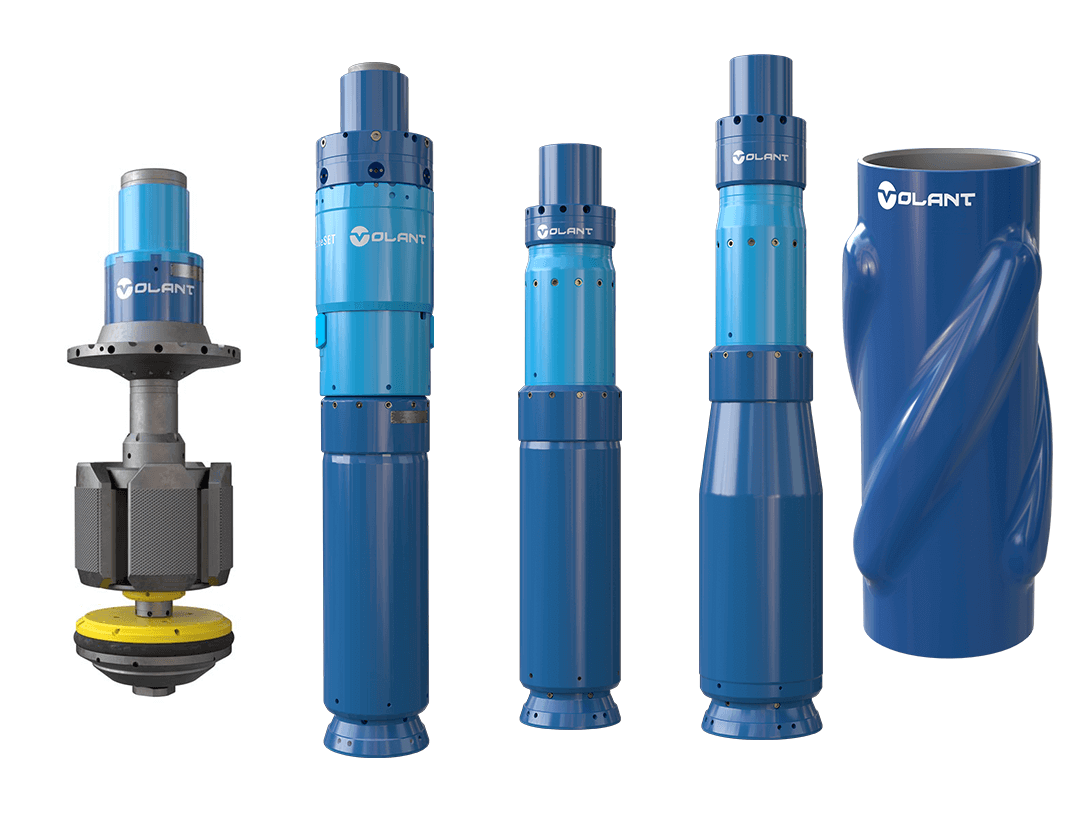

Volant’s rigid-steel centralizers provide positive standoff, mitigate buckling and facilitate rotation using crimp-on technology to overcome friction and other running challenges. This leads to improved run-ability of your casing string by saving time on the run. The sturdy, helical ribs provide positive stand-off and flow areas for solids removal, improved mud flow and a high-quality cement job.

The Volant Paddle Valve Plug Launcher enables the worry-free release of plugs through a remote pneumatic release system. The Plug Launcher directs cement into the annular space between the main body and cage, where plugs are housed. When plugs are ready to be launched, the paddles are pneumatically opened, redirecting cement to the top of the plug, forcing the plug out for a positive launch. With an integrated interlock, plugs are released in the correct sequence. Designed without protruding parts, the Plug Launcher improves safety on the rig floor during rotation and reciprocation.

Volant’s Cement Swivel connects in-line with the top drive quill and allows for cement to be pumped through a side-entry port while maintaining the ability to rotate and reciprocate the casing string, improving the integrity of the cement job. The Cement Swivel circumvents the need to pump cement through the top drive, eliminating the risk of cement setting in the top drive components when operated in-line with a Kelly Valve (or similar). With the option to install above or below a casing running tool, or even independently, the CST-2.0 is designed to reduce non-productive time required for tool changeover between casing running and cementing operations.

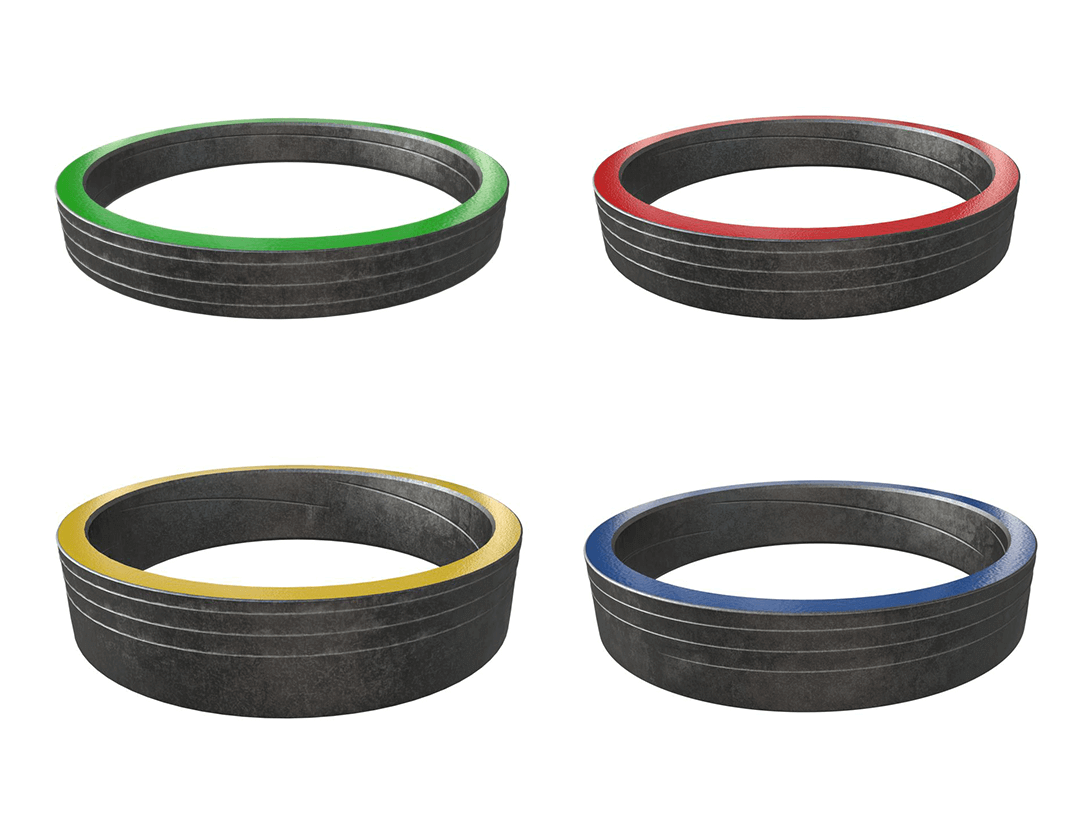

Volant’s DTR®️ and Multi-Lobe torque rings have been engineered to provide additional torque capacity for casing and tubing connections for the upstream market. They are designed to fit standard API casing and tubing connections, providing a cost-effective, enhanced connection solution with a short-lead time.

Disclaimer: "Volant images are property of Volant Products Inc. and have been licensed to Chisida Energy Services Ltd. for their use" CRTi®, HydroFORM® and DTR® are registered trademarks of Noetic Technologies Inc.